Silicone-free plunger for ophthalmic drug delivery

Gore recently launched its silicone-free GORE IMPROJECT Plunger for 0.5-mL pre-filled syringes for the delivery of ophthalmic drugs.

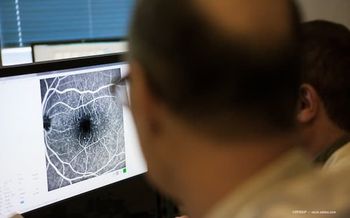

W. L. Gore and associates (Gore) announced the launch of its silicone-free GORE IMPROJECT Plunger for 0.5-mL pre-filled syringes that are designed specifically to facilitate the delivery of ophthalmic drugs. According to a company press release, the 0.5-mL prefilled syringe product addresses particle and silicone sensitive applications and is targeting ophthalmic/retinal and to a lesser degree, gene therapy applications.

The applications of the plunger, the use of which also includes ophthalmic intravitreal injections, complements theGORE IMPROJECT 1-mLL plunger launched in mid-2018.

This new product is in contrast to conventional pre-filled syringe systems that use silicone to provide a seal and act as a lubricant between the barrel and the plunger. Complications of products that include silicone in their manufacturing process have been reported in the literature and include elevated subvisible particulate levels, silicone accumulation in the eye resulting in floaters, silicone-induced protein aggregation resulting in immunologic responses, and ocular inflammation and elevated intraocular pressure. Syringes that contain silicone also have been associated with increases in particle counts and fatty acid creation over time.

The company claims that the new plunger enables syringe systems to achieve particulate levels below the limits of the United States Pharmacopeia 789 subvisible particle standard.The plunger can be terminally sterilized and has been shown to provide suitable break loose and glide force and container closure integrity performance when used with appropriate syringe components and commercial fill and finish processes.

Gore Syringe Business Leader, Emily Oliver commented, “Gore’s 0.5-mL plunger, in combination with a silicone-free glass or advanced polymer syringe barrel, enables pharmaceutical companies to achieve what they’ve been asking for, ie, to reduce the risk associated with silicone by enabling its removal from the syringe plunger and barrel.”

Development of this new product was achieved by close collaboration with pharma companies, chief marketing officers, terminal sterilization companies, machine companies that design equipment for fill operations, and leading syringe barrel suppliers. “We involved key partners to ensure the product meets the needs of stakeholders throughout the value chain including rigorous fill and finish requirements. This is a breakthrough solution for the industry and was designed with the goal of improving patients’ lives,”according to Russ Hornung, Gore Business DevelopmentManager.

Newsletter

Keep your retina practice on the forefront—subscribe for expert analysis and emerging trends in retinal disease management.